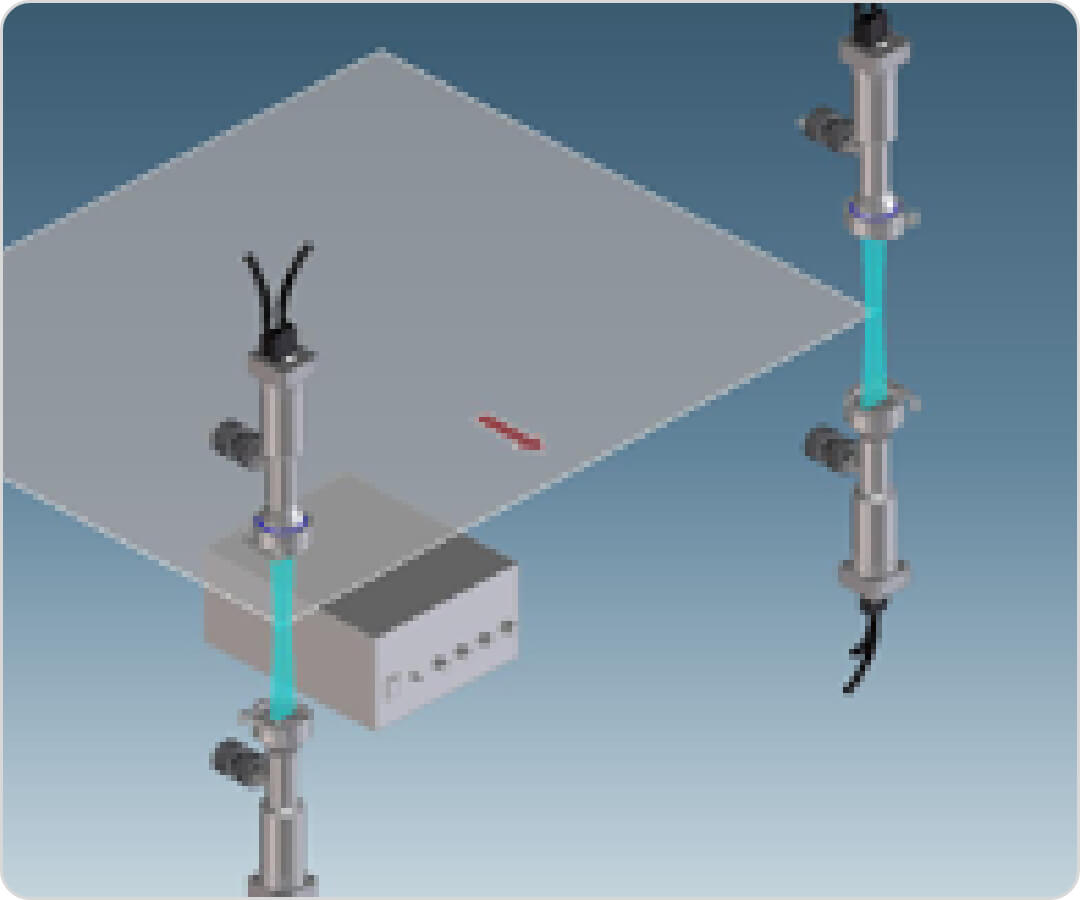

Machine Vision Optical Design

Select Optimal Hardware through Sample test(Camera, lens, Lighting etc)

-

Machine Vision

-

-

-

Optimized Optical System Design Capabilities

Optimization for Customer Requests(Defective form, Size, etc)

- Securing AI, Big Data-based Inspection Algorithm

- Increase Sales Power by Enabling Turnkeys and Module sales with Modularization

-

Optimized Optical System Design Capabilities

-

- Securing Real-time Image Processing Algorithms

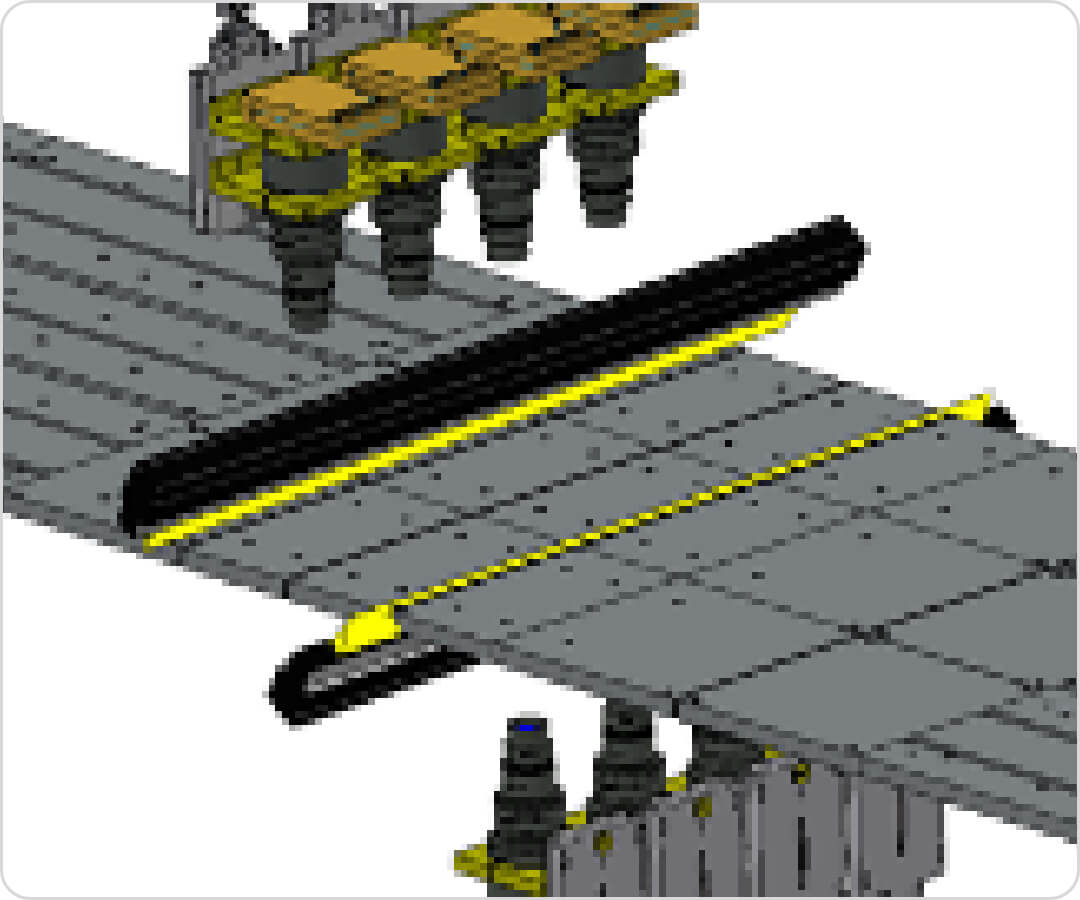

- Securing Mechanical Simulation and Production Techniques for Optimal Inspection Environment

- In-house Developed AI System utilizes our Optical Systems and Algorithms, allowing it to be sold not only Domestic Samsung and LG, but also Overseas such as Japan and China

-

Optical Design

-

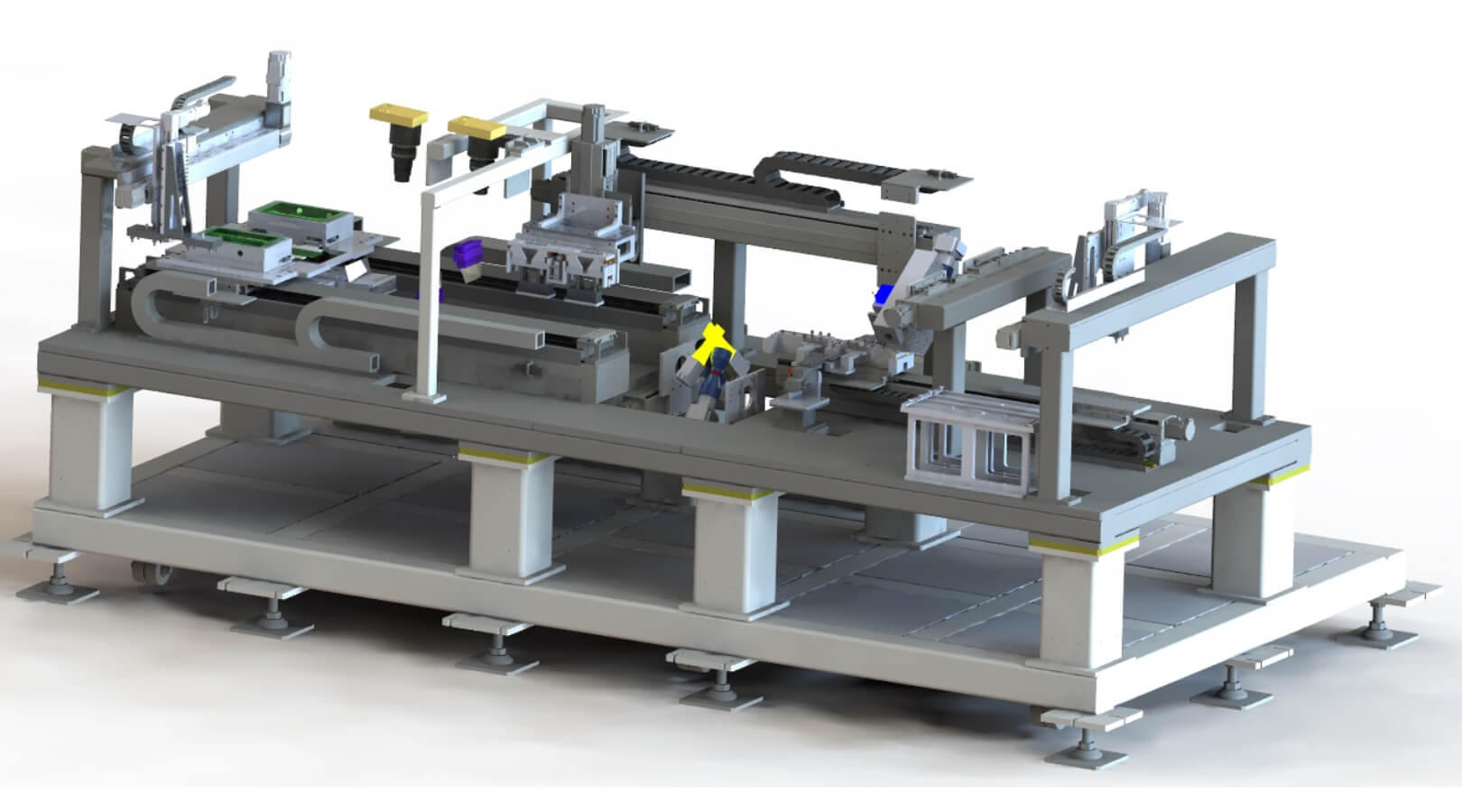

Mechanical Design

Design each part of Instrument and Logistics system

Design System Instrument layout -

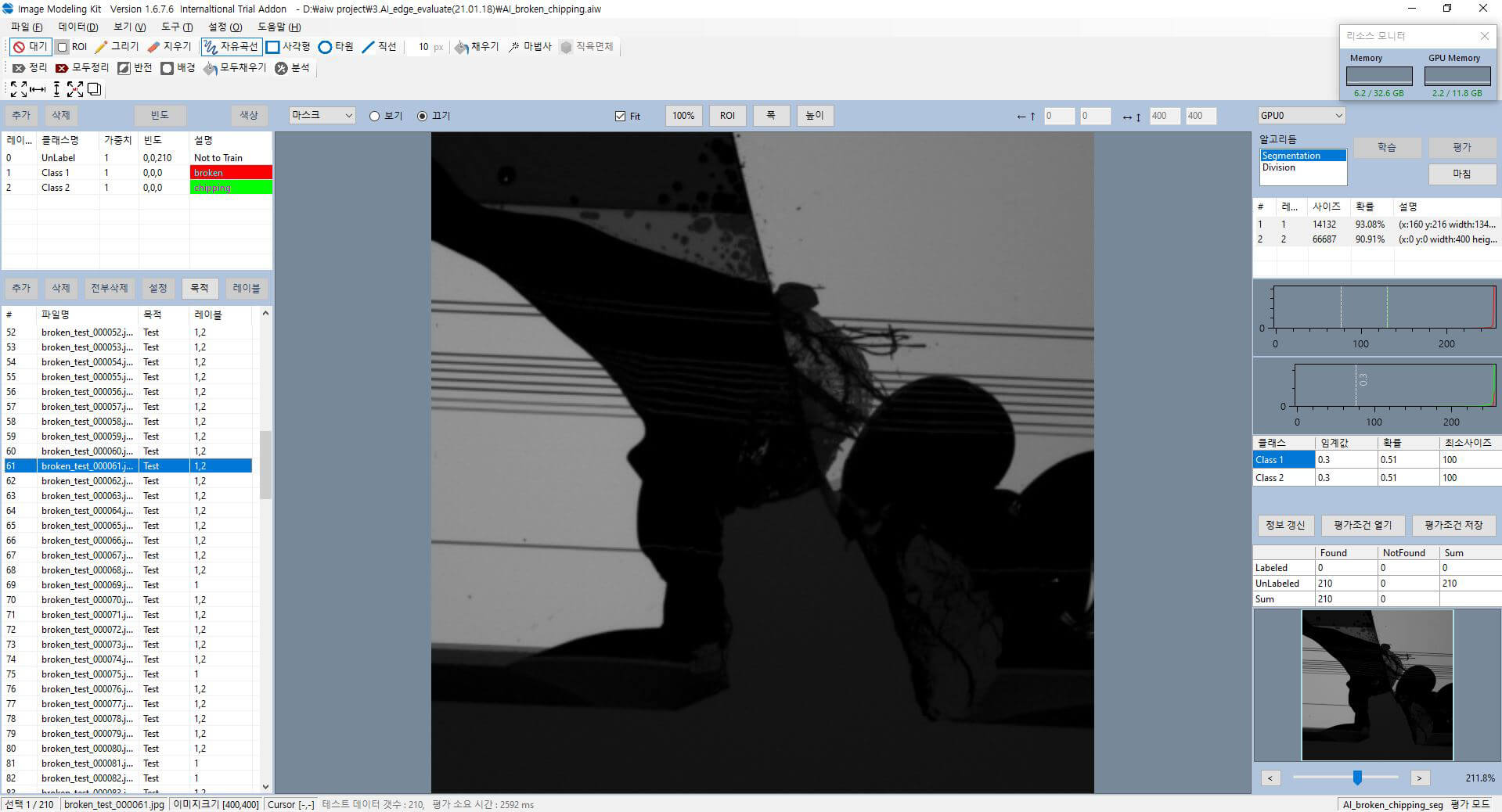

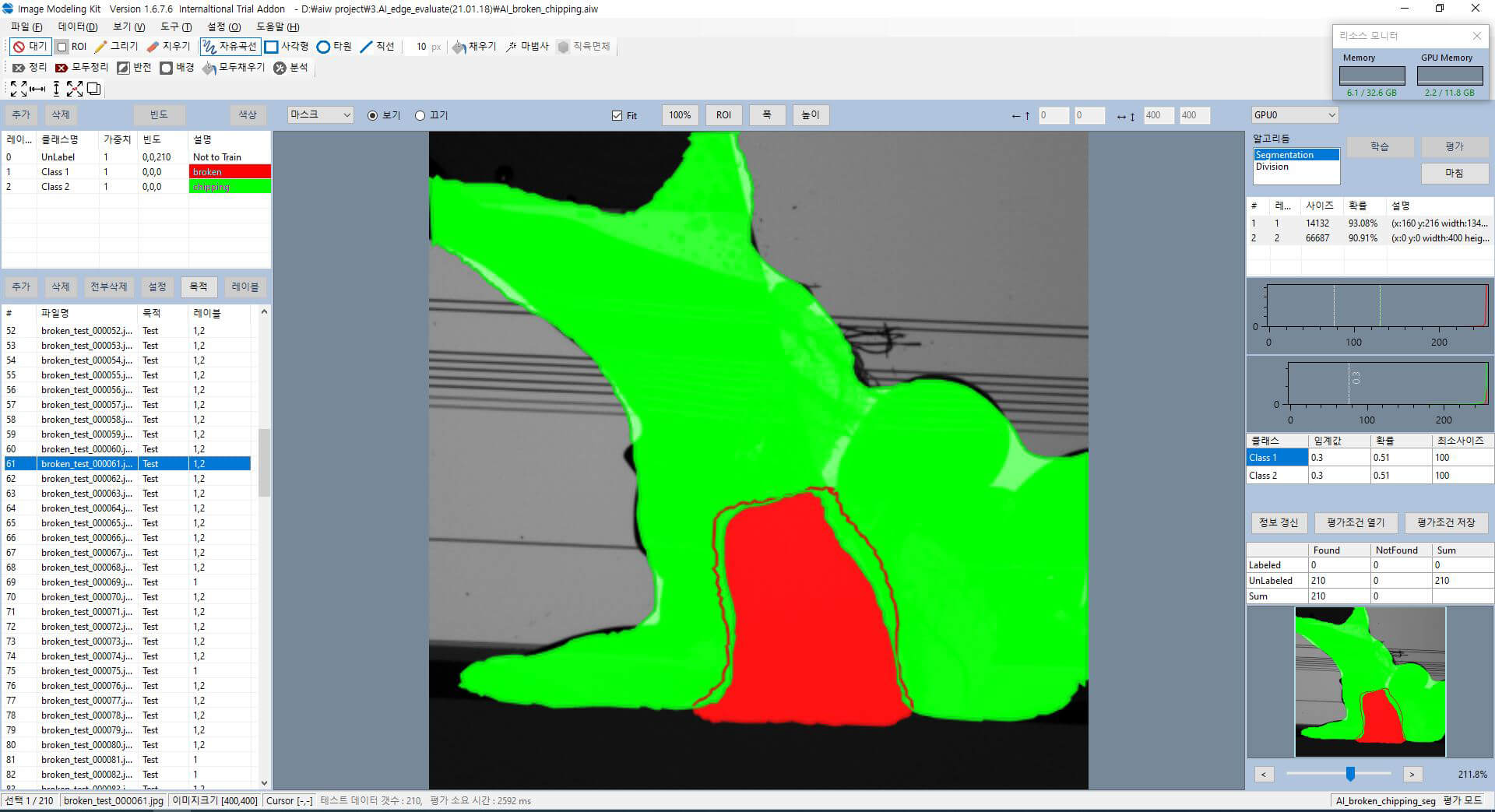

S/W Development

Machine Vision program

AI, Big Data based Inspection program

Motion Control/user interface

-

-

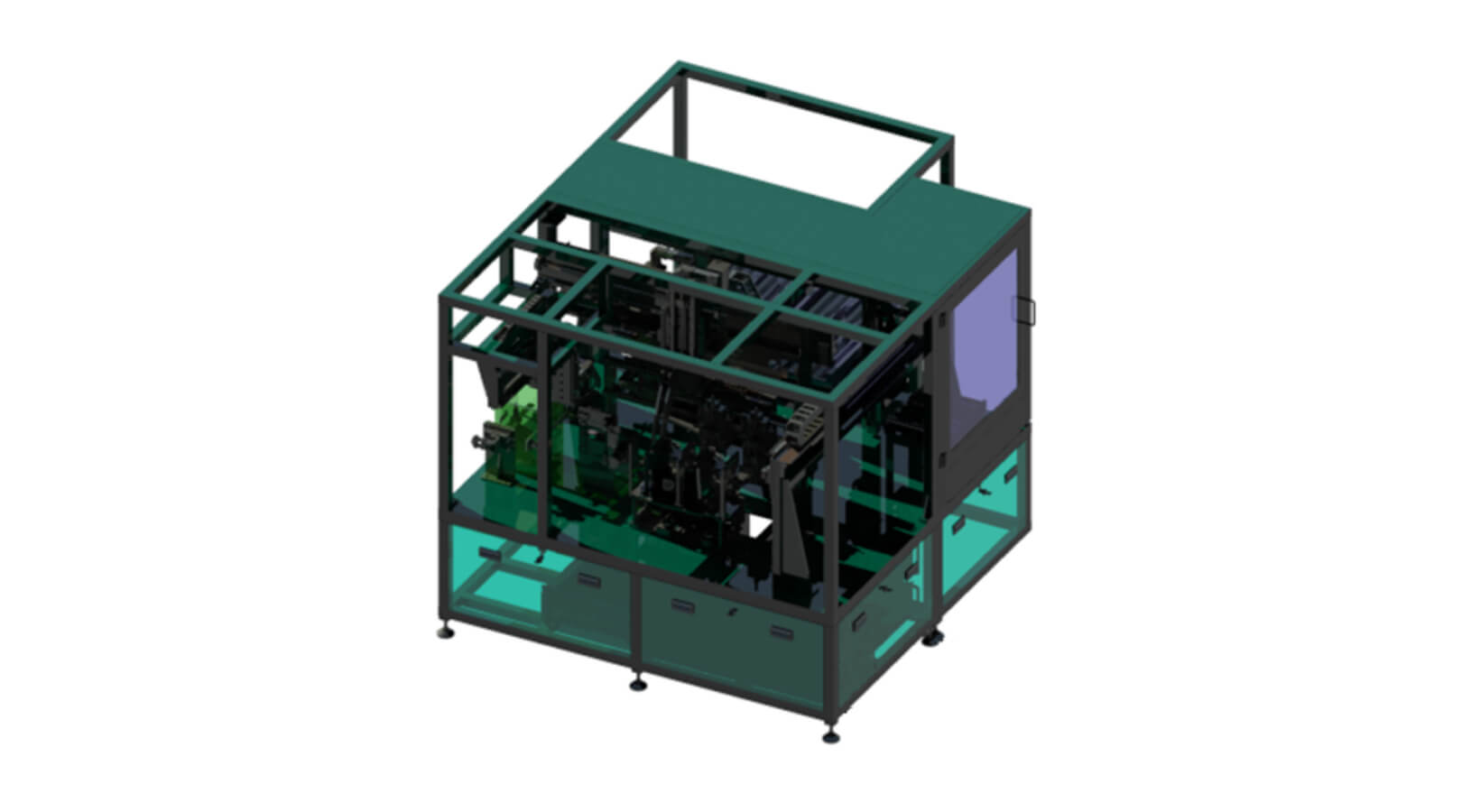

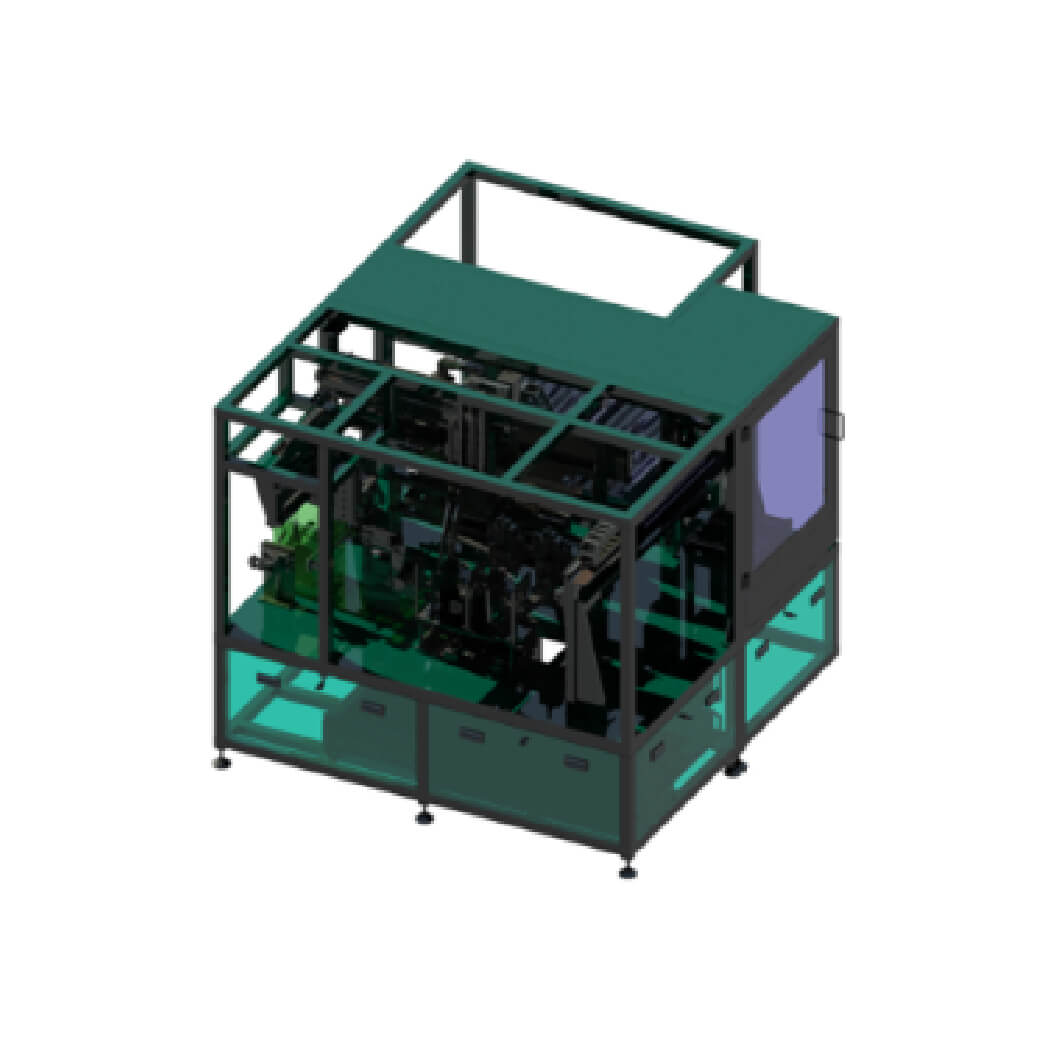

AI Inspection Machine

Product Overview

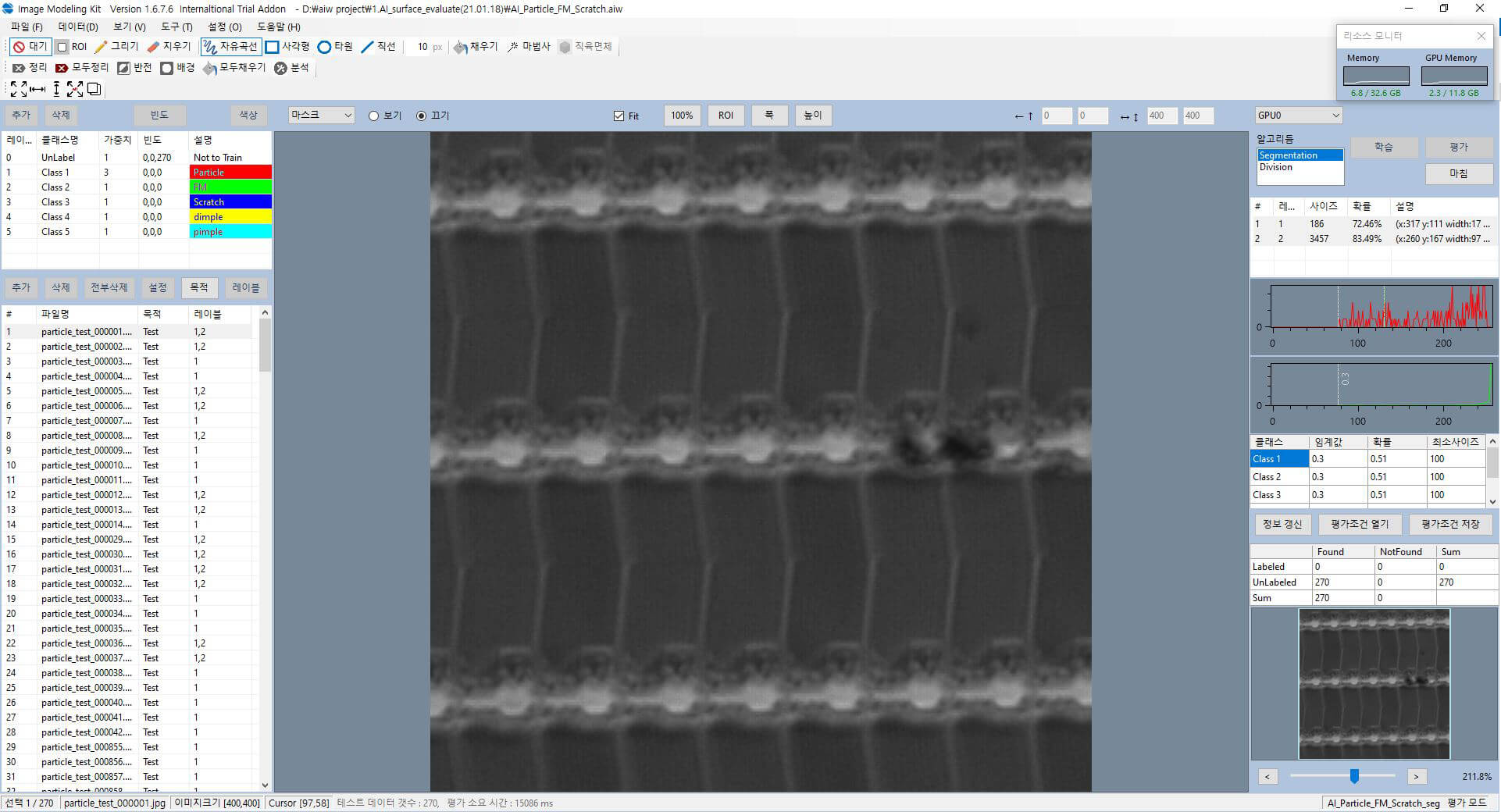

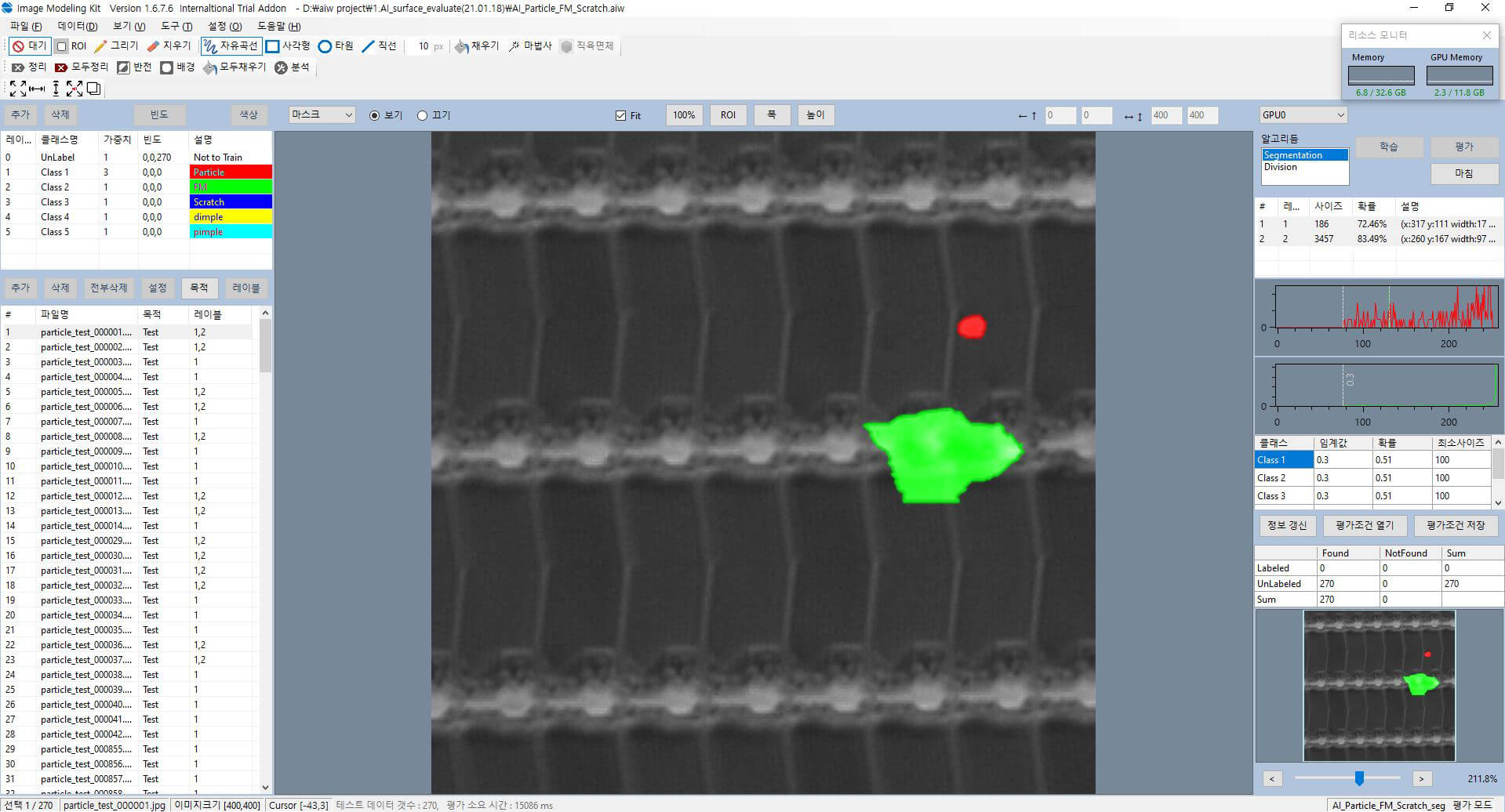

- A Device that Automatically Detects Various Defects of Helical gear parts of Automobile Transmission using Vision System

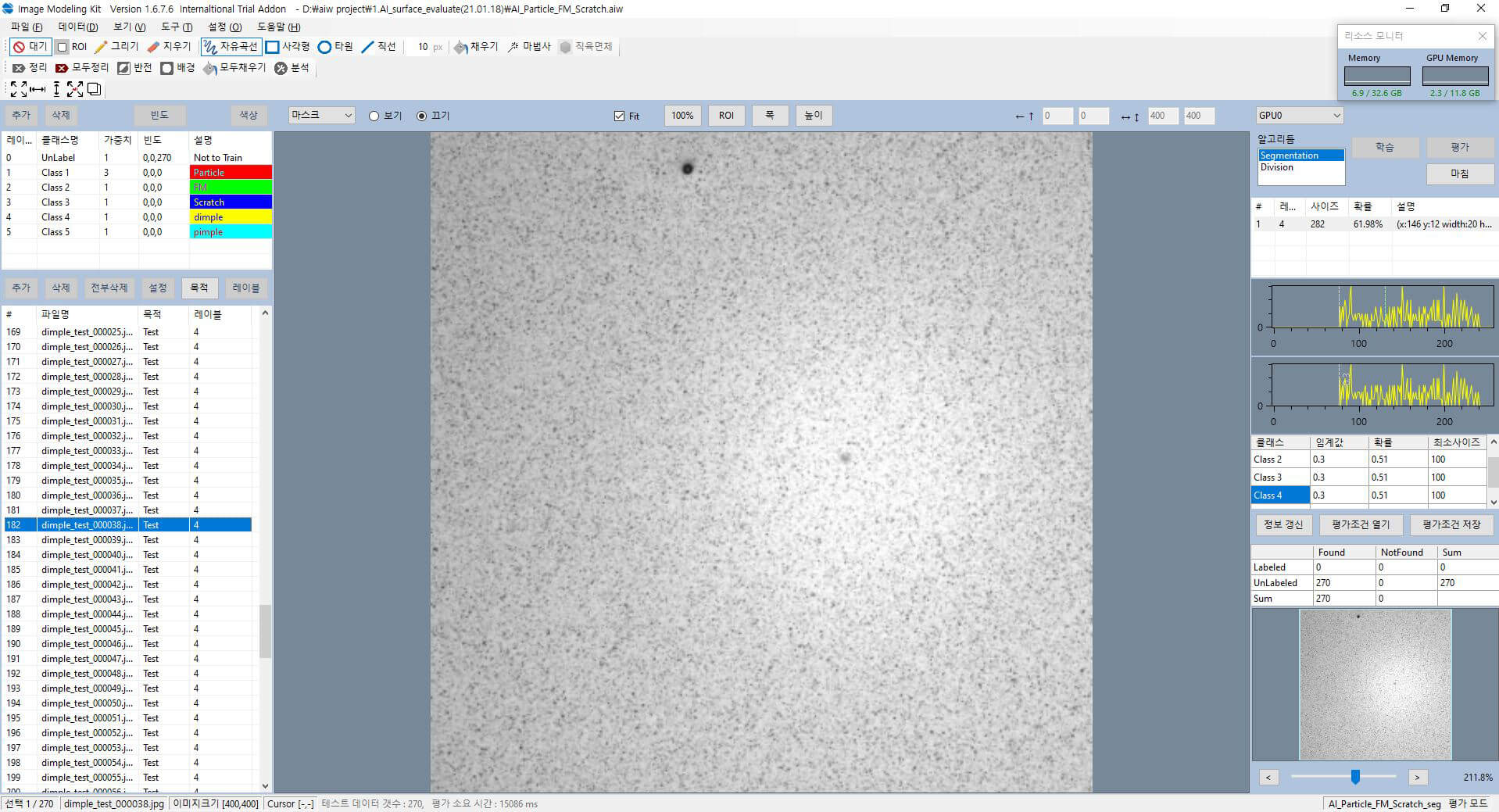

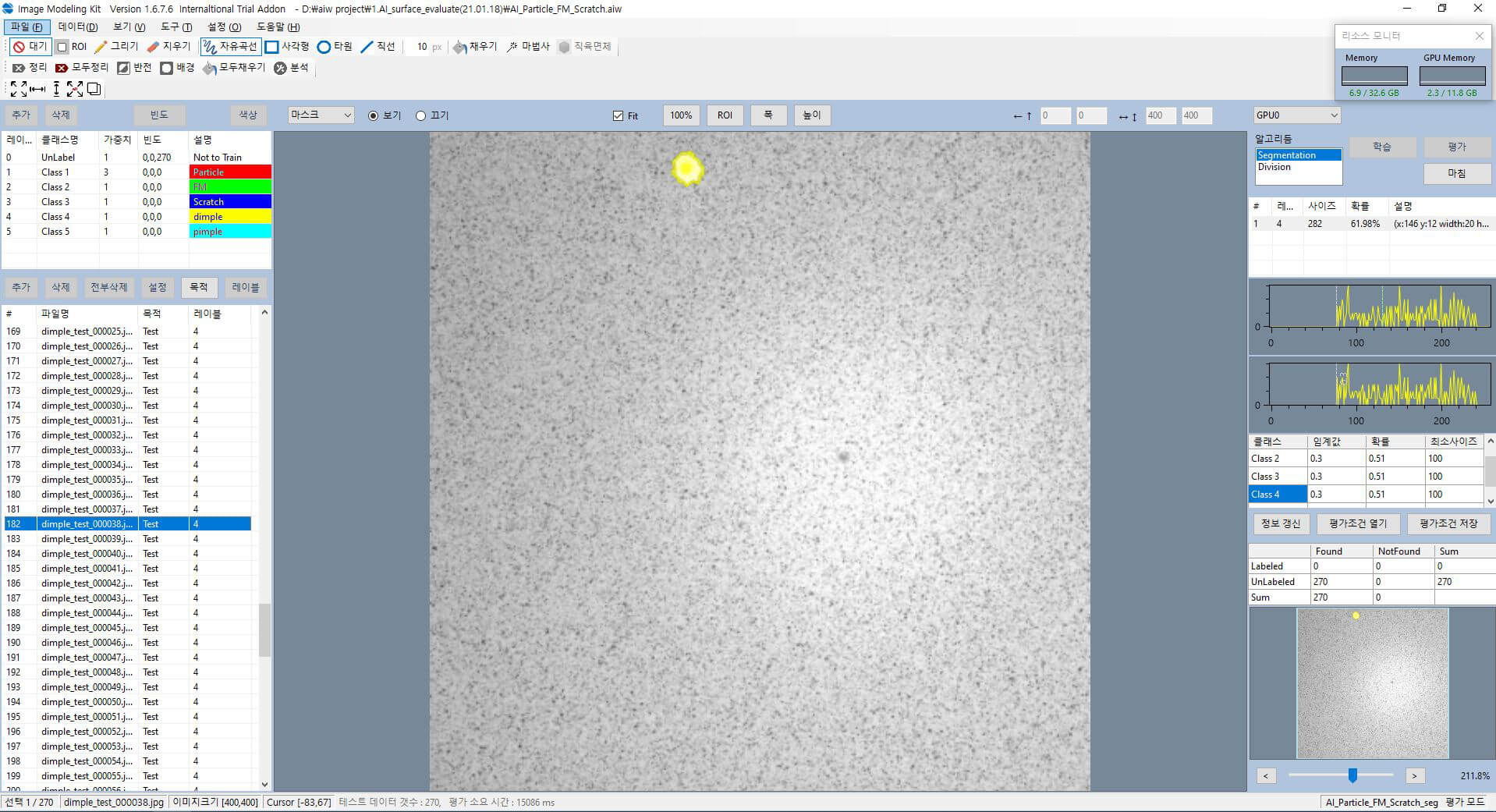

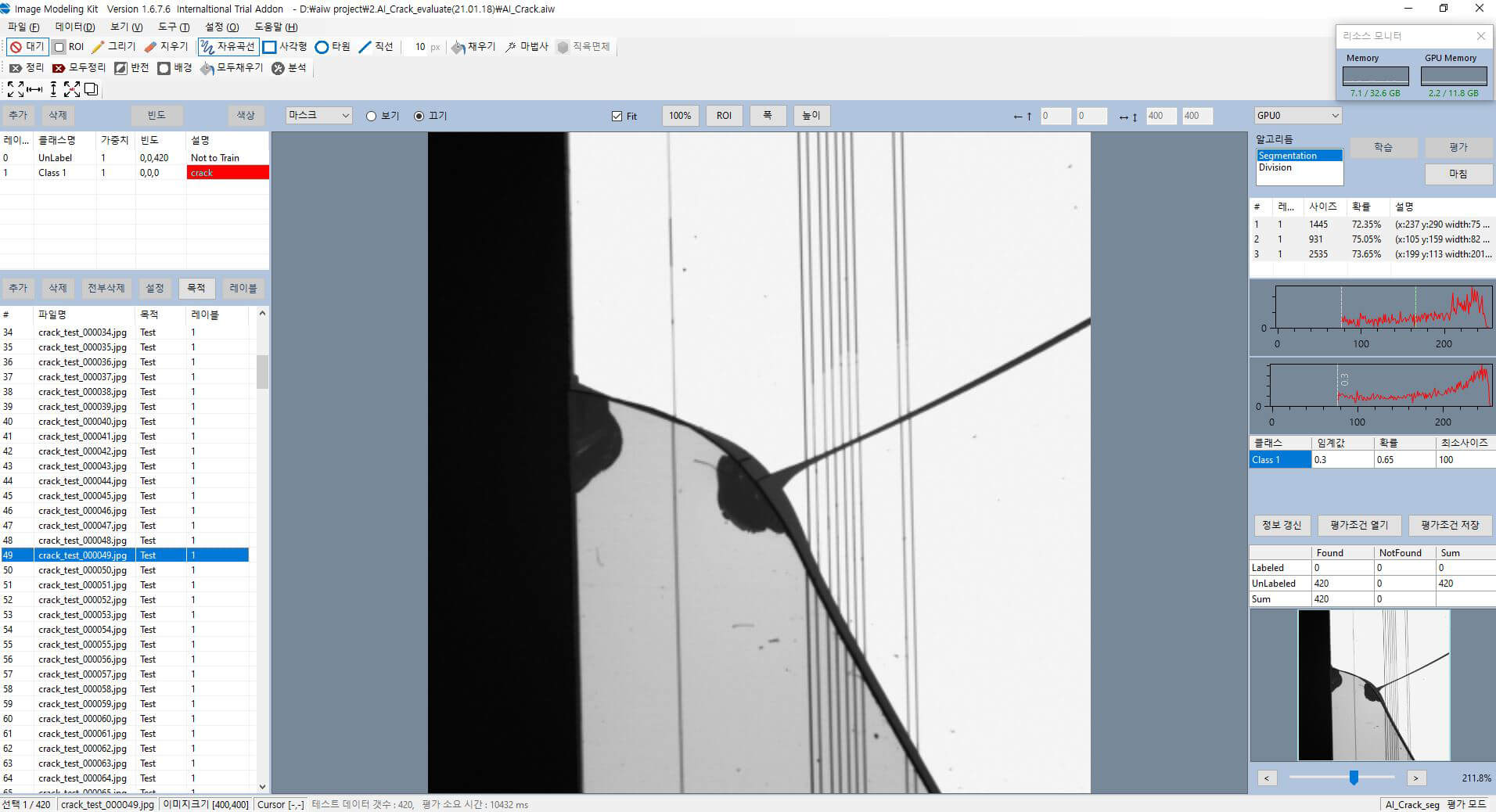

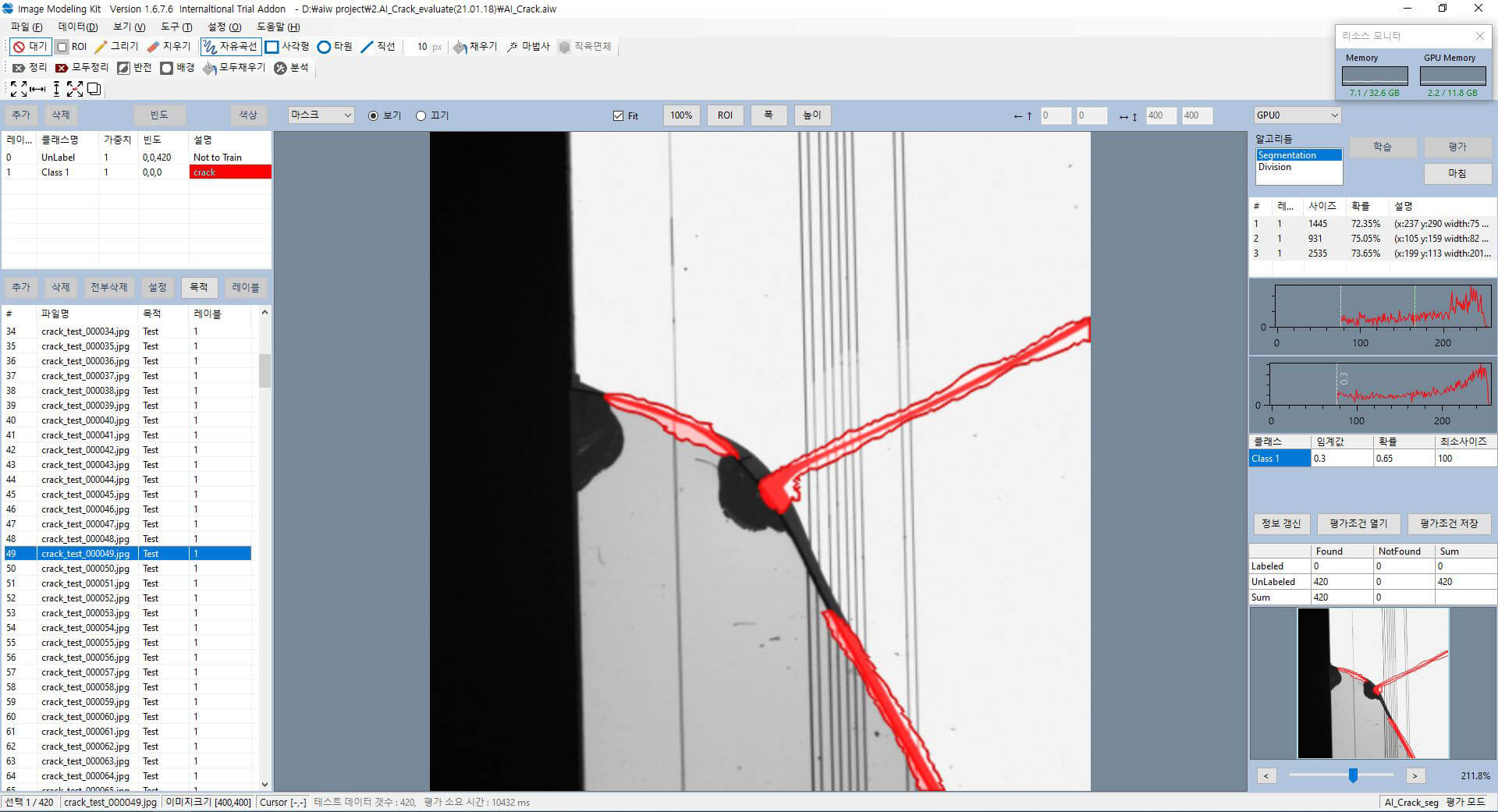

- Obtaining Images by Camera and Detecting Defects through AI, Big Data based Inspection program

Main Features

- Inspect using Line Scan, Area Scan Camera

- Classification and Detection of Types and Location of Defect through Deep Learning Inspection

-

AI Inspection Machine(Display)

Product Overview

Essential Process Equipment

-

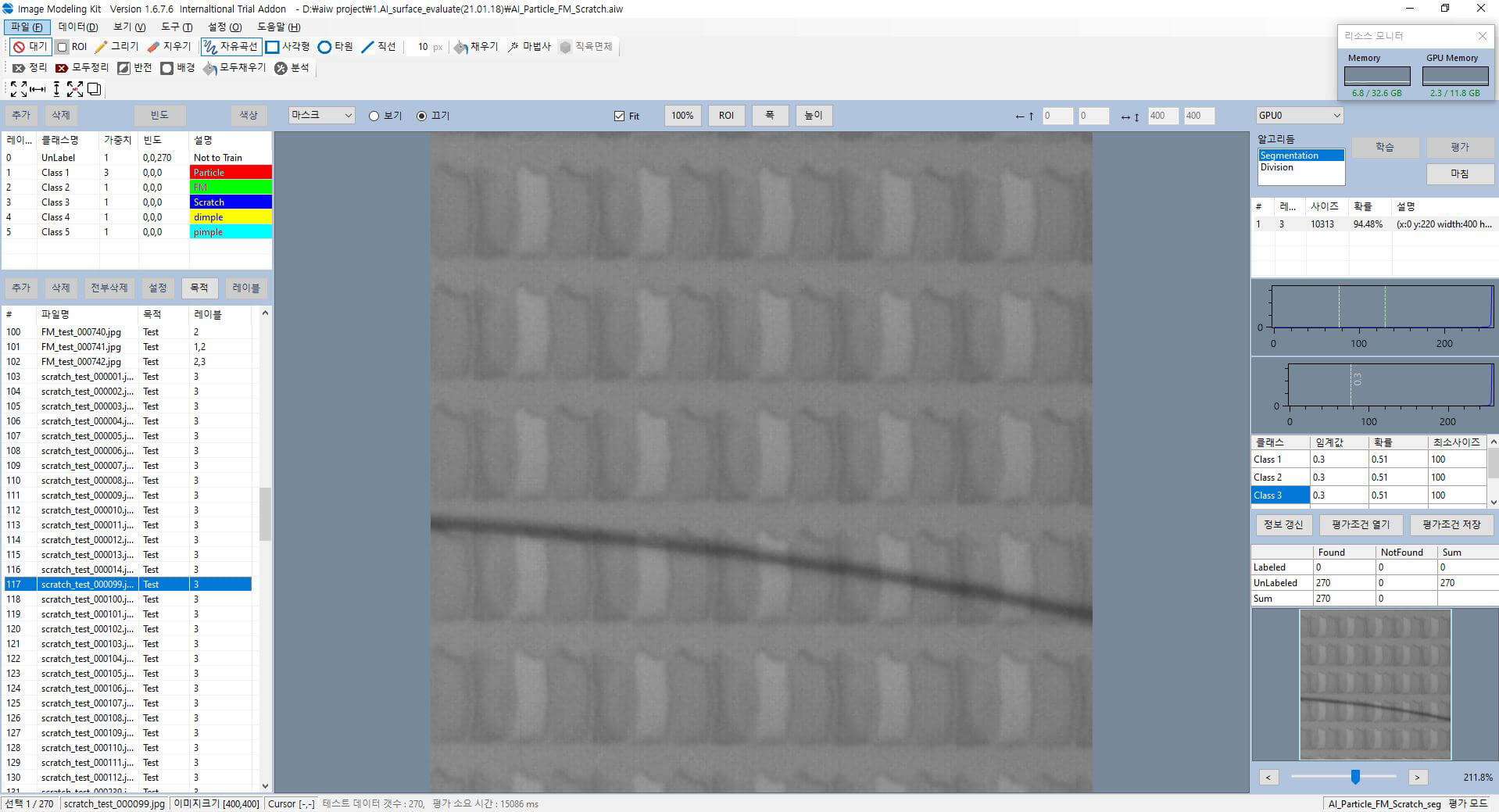

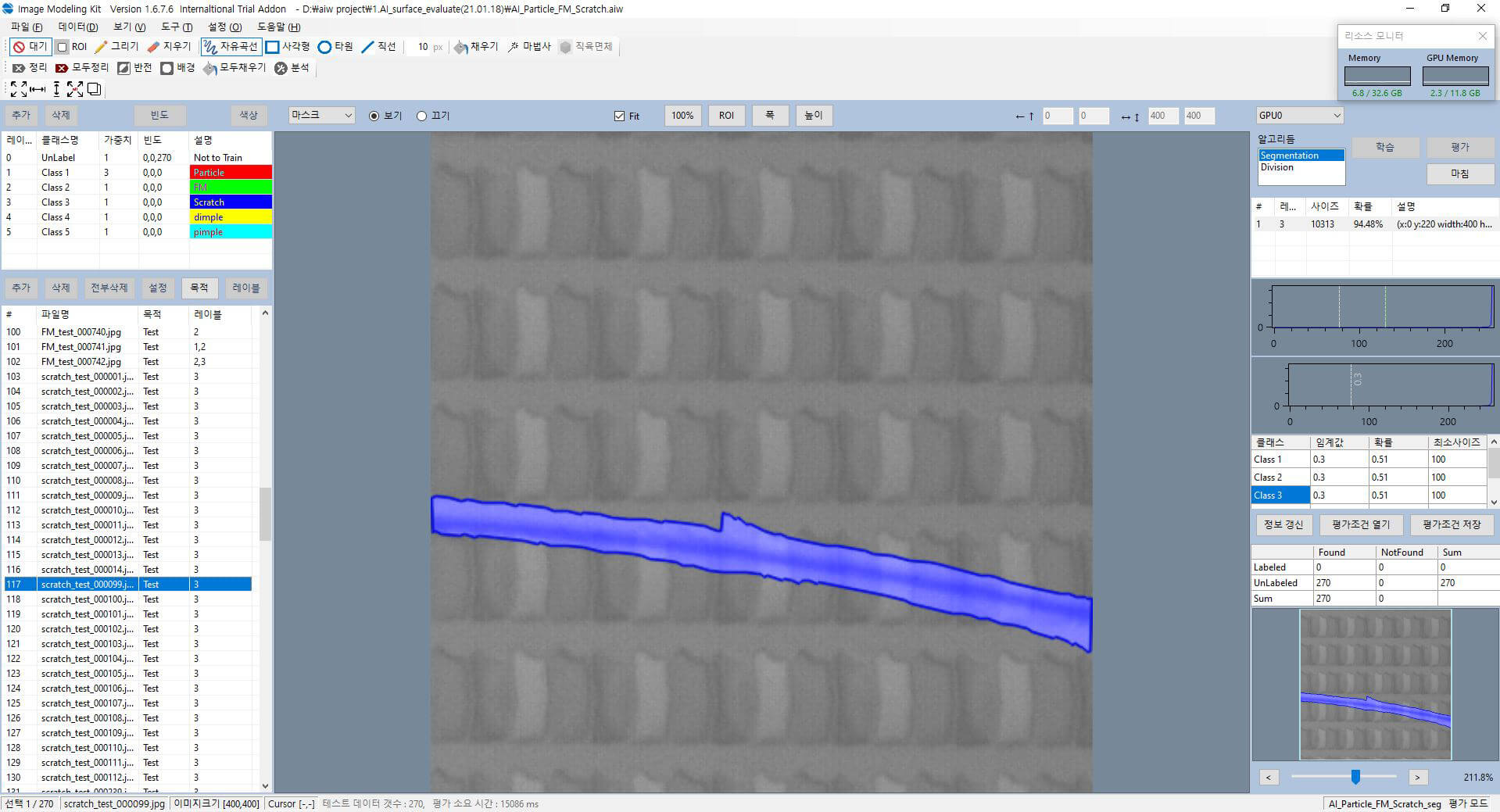

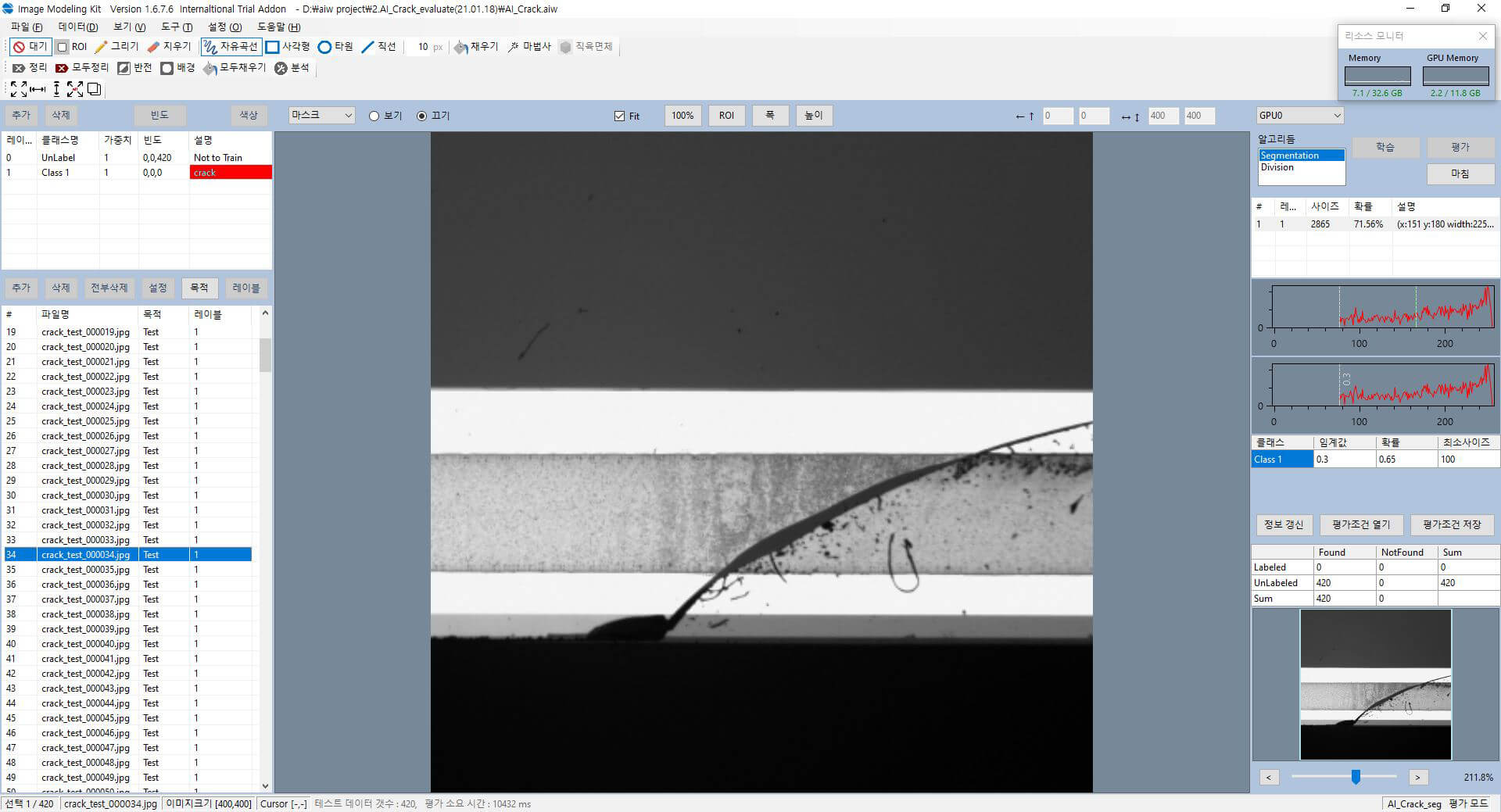

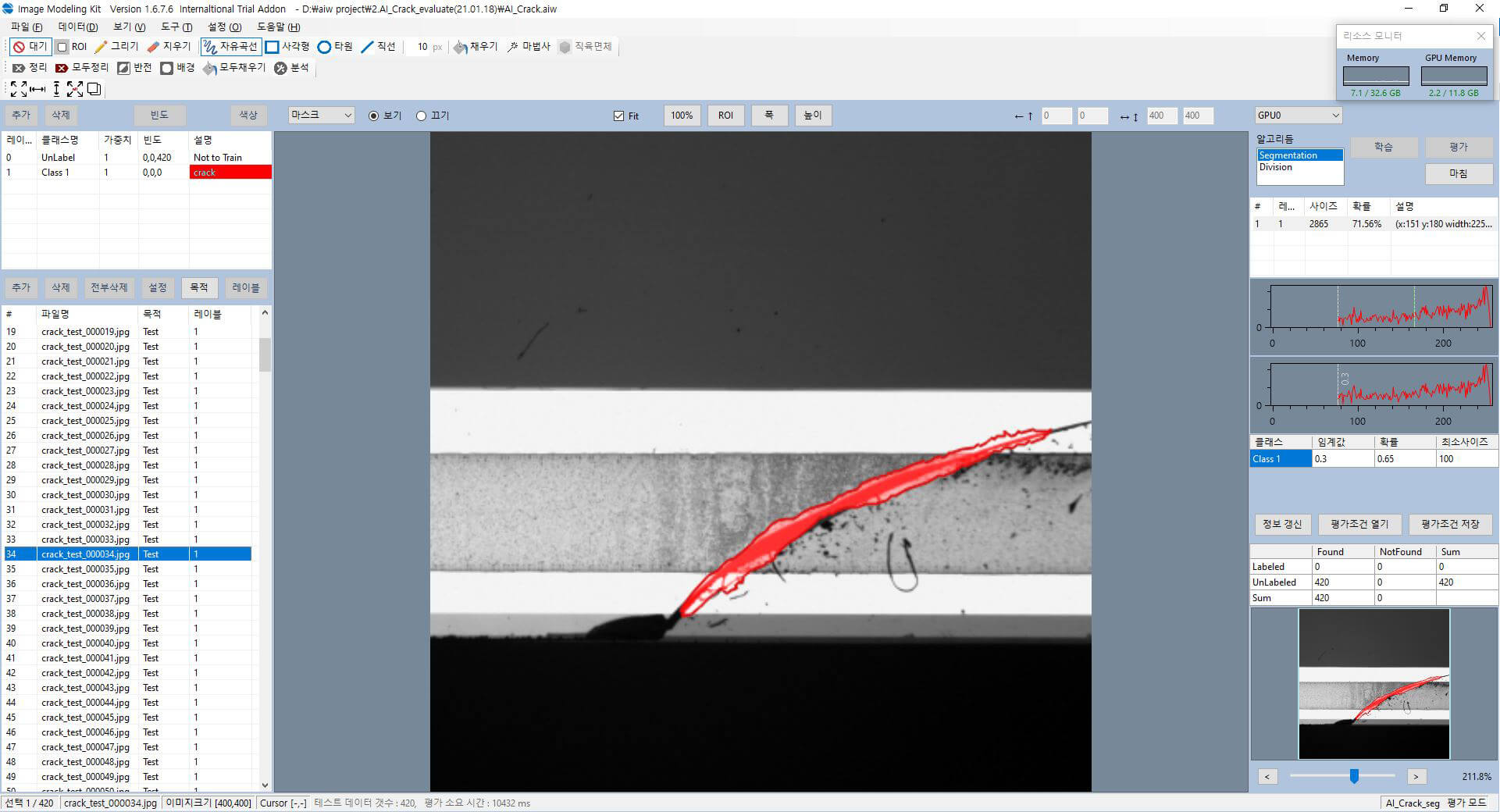

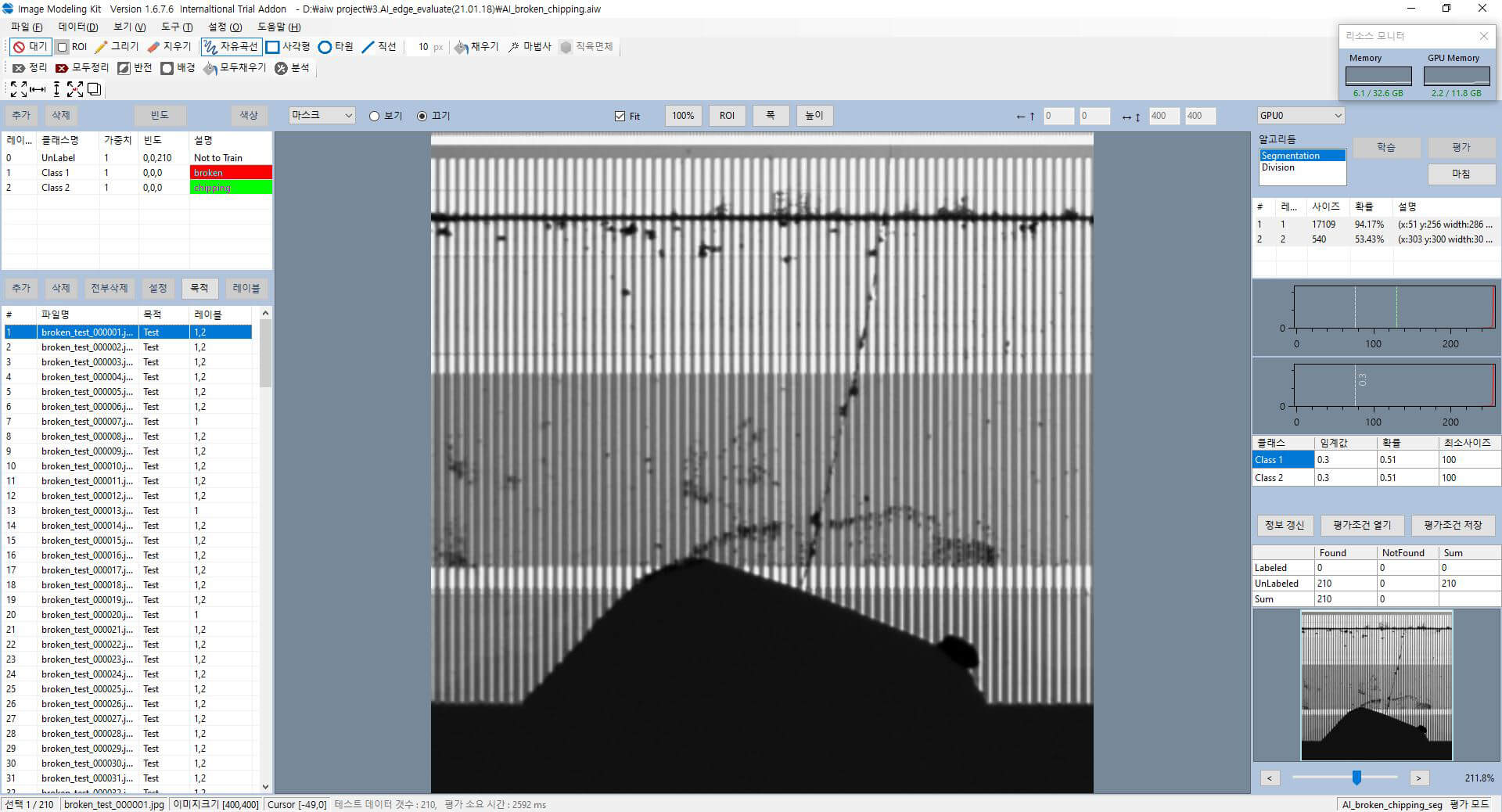

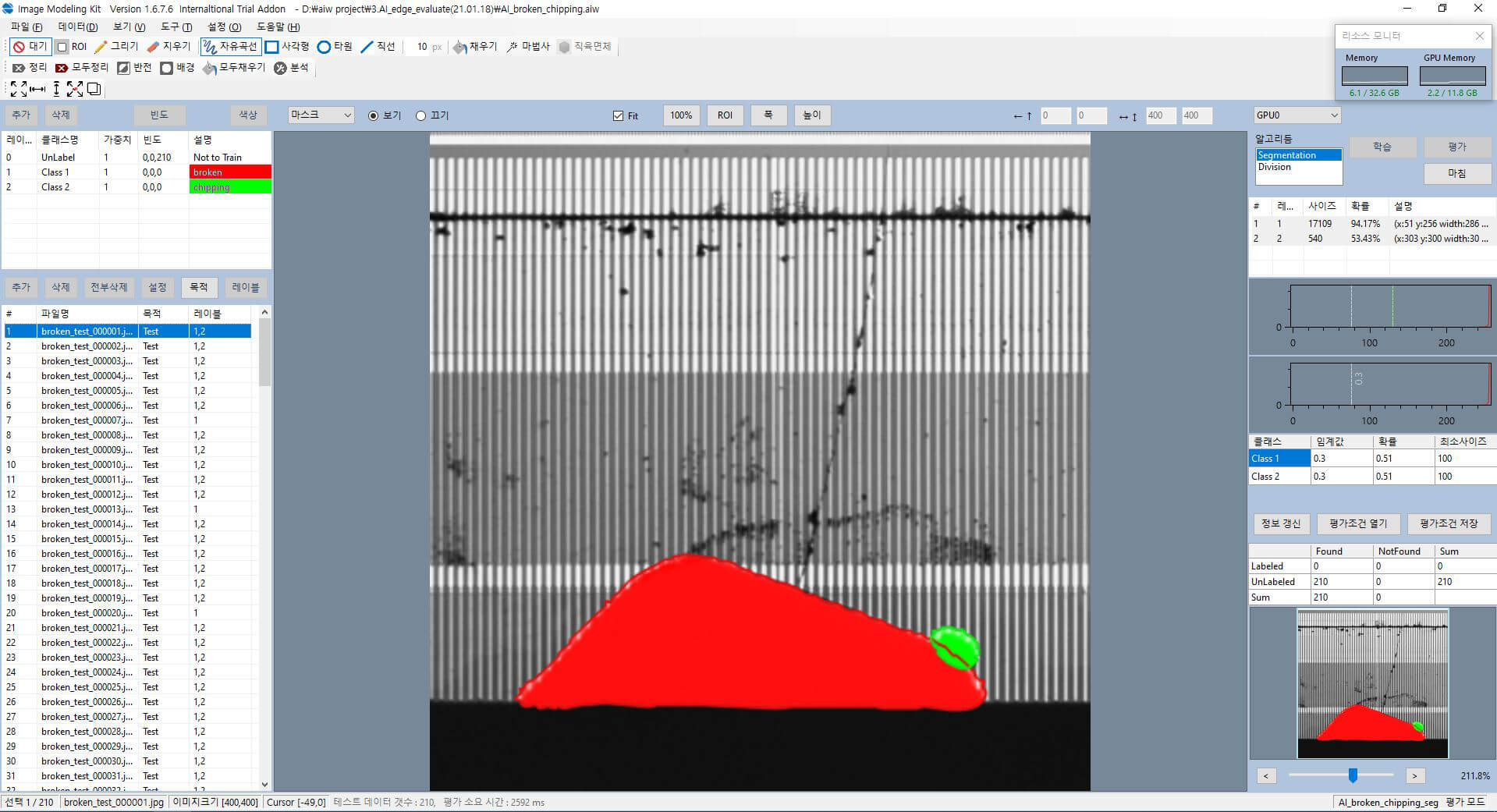

This system uses the top and bottom of Panel's Surface & Edge vision system

to detect Amount of Polishing, Burr, Chip, Crack, Broken, Scratch, Foreign Substance

Inspection Area

- Glass Surface Top Side

- Glass Surface Bottom Side

- Glass Edge Top Side

- Glass Edge Bottom Sides

Inspection Item

- Amount of Polishing, Burr , Chipping, Broken, Crack, Scratch, Foreign Substance

Main Features

Secured Core Technology

- Securing Foreign Material Inspection Technology using Camera

- Traditional Inspection + AI Solution Application

- Maximize Detection rate of Microcracks

-

This system uses the top and bottom of Panel's Surface & Edge vision system